Every year, millions of Americans rely on generic drugs to manage chronic conditions, treat infections, or control pain. These medications are cheaper, widely available, and legally required to work the same as brand-name versions. But behind that simplicity lies a hidden risk: contamination. In 2022, generic drug contamination was behind nearly 4 out of every 10 drug recalls in the U.S. - and most of these weren’t caught until patients got sick.

Contamination doesn’t mean a pill has dirt on it. It means something dangerous got mixed in during manufacturing - a chemical residue from another drug, a bacteria, a metal particle, even a fungal spore. These aren’t rare accidents. They’re systemic failures tied to how these drugs are made, where they’re made, and who’s watching.

How Contamination Happens in Generic Drugs

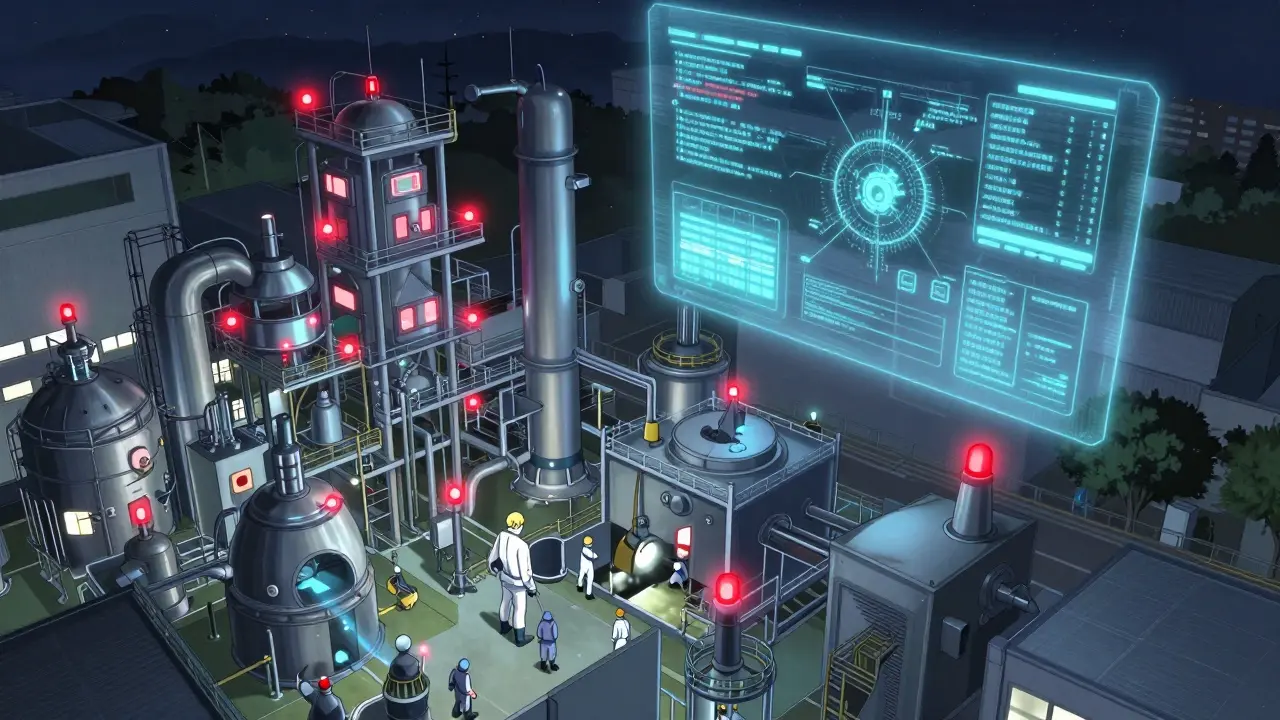

Generic drugs aren’t made in clean, quiet labs. They’re made in large factories - often overseas - where hundreds of different drugs are produced on the same equipment. One day, it’s metformin for diabetes. The next, it’s a blood thinner. If cleaning between batches isn’t perfect, tiny traces of the previous drug stay behind. That’s cross-contamination.

According to FDA data, 80% of the active ingredients in U.S. generic drugs come from just two countries: India and China. These facilities face pressure to cut costs. A single production line can churn out millions of pills. Cleaning it thoroughly takes time, water, and expensive chemicals. Many manufacturers skip full validation because they can’t afford it - or because they think no one will check.

Even the people working there contribute. A single person in a cleanroom sheds about 40,000 skin cells per minute. Each cell carries thousands of particles. If staff aren’t trained properly or don’t wear the right gear, they become the biggest source of contamination. Studies show personnel are responsible for 75-80% of airborne particles in manufacturing areas.

Some contamination comes from how the drug is handled after it’s made. Pharmacists breaking open glass ampules, piercing vials with needles, or withdrawing liquids can introduce microbes. OSHA found that 62% of hazardous drug contamination incidents in pharmacies involved needle use alone.

Why Generic Drugs Are More at Risk

Brand-name drugs and generics must meet the same FDA standards. But the reality is different. Generics are sold at prices that leave little room for error - or investment. The average profit margin on a generic drug is 20-25%. For brand-name drugs, it’s 60-70%.

That gap shows up in inspections. In 2022, 8.3% of generic drug manufacturing sites received FDA warning letters for contamination control failures. For brand-name facilities, it was 5.1%. In India, where many generics are made, contamination-related violations hit 12.7% of inspected sites - more than double the rate in U.S.-based plants.

Older facilities are worse. Plants built before 2000 have 34% higher contamination risk because they weren’t designed for modern cleanroom standards. Vertical integration helps - companies that make their own active ingredients have 22% fewer contamination incidents. But most generics rely on third-party suppliers, adding layers of risk.

Some companies do it right. Teva’s facility in Bologna, Italy, cut cross-contamination by 78% using closed manufacturing systems. Mylan’s plant in Morgantown reduced incidents by 82% by installing real-time particle monitors and upgrading gowning procedures. But these are exceptions, not the norm.

What’s in the Drugs? The Real Threats

Not all contamination is the same. Some substances are toxic at very low levels. For example, nitrosamines - cancer-causing chemicals - were found in blood pressure medications like valsartan in 2018. That single contamination event led to over 2,300 recalls across eight countries and cost more than $1.2 billion.

Other risks include:

- Microbial contamination: Bacteria or mold in oral pills. USP standards say non-sterile drugs must have fewer than 1,000 colony-forming units (CFU) per gram. But in 2021, the FDA found a generic metronidazole batch with 15,000 CFU - 15 times over the limit.

- Chemical residues: Leftover drug from a previous batch. The FDA requires cleaning to remove 10 parts per million (ppm) of residue. But for highly potent drugs - like cancer treatments - even 1 ppm can be dangerous. Experts say the 10 ppm rule is outdated for modern medicines.

- Foreign particles: Metal, glass, or plastic fragments. One patient developed severe skin burns from a generic hydrocortisone cream contaminated with copper particles. The FDA documented it in 2021.

These aren’t hypothetical. Between 2020 and 2022, over 1,200 reports of suspected contamination were filed with the FDA’s MedWatch system. Nearly 400 involved real patient harm - rashes, infections, organ damage, even hospitalizations.

How Prevention Works - and Why It Often Fails

Good Manufacturing Practices (GMP) exist for a reason. They require:

- Validated cleaning procedures - proven to remove residue to safe levels

- Environmental monitoring - air and surface tests for microbes and particles

- Personnel training - 8-12 hours of contamination prevention training annually

- Facility design - ISO Class 8 for non-sterile drugs, ISO Class 5 for sterile ones

But implementation is uneven. FDA inspections in 2022 found:

- 34% of facilities had inadequate environmental monitoring

- 28% didn’t validate their cleaning agents properly

- 22% had poor change control - no system to track when equipment or processes changed

Fixing these problems isn’t cheap. Upgrading a medium-sized plant to meet modern standards costs $2-5 million. Adding closed systems for high-risk drugs adds another half-million to $2 million per line. Most generic manufacturers can’t - or won’t - spend that.

Some are trying new tech. Rapid microbiological methods can detect contamination in 4 hours instead of 7 days. Sixty-three percent of top generic makers now use them. The FDA is testing AI systems that analyze 15,000 data points per facility to predict contamination before it happens. These tools are promising - but still rare.

What Happens When Contamination Is Found?

Once contamination is confirmed, the FDA can force a recall. But the system is slow. In 2022, the average time from discovery to public recall was 18 days. During that time, patients keep taking the drug.

Manufacturers must report contamination to MedWatch. But only 1 in 10 adverse events are reported by doctors or patients. Pharmacists are often the first to notice something’s wrong - a pill that looks different, smells odd, or causes unexpected side effects.

One pharmacist on Reddit reported finding blue specks in a generic metronidazole batch. Lab tests confirmed copper contamination. Another reported a batch of levothyroxine that caused heart palpitations in multiple patients. The pills were later found to have inconsistent active ingredient levels - a different kind of failure, but just as dangerous.

When a recall happens, it’s expensive. The average cost per contamination recall is $18.7 million. That’s why some companies delay reporting - hoping the problem will disappear. But the FDA now uses a smarter system called PREDICT. It flags 37% more risky imports than before, and in 2023, over 8% of flagged shipments were stopped at the border.

What You Can Do as a Patient or Pharmacist

You don’t have to wait for a recall to protect yourself.

- Check the pill. If a generic looks different from your last bottle - color, shape, markings - ask your pharmacist. Don’t assume it’s the same.

- Report anything odd. If you feel worse after switching to a new generic, or notice unusual symptoms, file a report with MedWatch. Your report could help stop a batch before more people are harmed.

- Ask about the manufacturer. Not all generics are equal. Some brands - like Teva, Mylan, and Sandoz - have better track records. Your pharmacist can tell you who made your drug.

- Use mail-order pharmacies carefully. Many contamination incidents are tied to unregulated online sellers. Stick to licensed pharmacies.

- For pharmacists: Test suspicious batches. Even if you can’t do full lab tests, check for visible particles, odd odors, or crumbling tablets. Document everything. Your notes could save lives.

The truth is, most generic drugs are safe. But safety isn’t guaranteed. It’s earned through constant vigilance - by regulators, manufacturers, pharmacists, and patients.

What’s Changing in 2026?

Things are improving - slowly. Since January 2023, all sartan-class blood pressure drugs must be tested for nitrosamines. The FDA is expanding its AI monitoring to more facilities. By 2024, they plan to use machine learning to predict contamination risks before inspections even happen.

Manufacturers are also being pushed harder. The European Medicines Agency now requires the same contamination controls for drugs sold in both the U.S. and EU. That’s forcing many overseas plants to upgrade - or lose access to one of their biggest markets.

Still, the system is under strain. The FDA inspects only 1% of imported drug shipments. That’s not enough. Experts agree: the current framework was built for a simpler time. Today’s supply chains are global, complex, and fast-moving.

But progress is possible. The same technology that tracks your Amazon package can now track a vial of medicine from factory to pharmacy. If we demand transparency, and if regulators enforce standards - not just on paper, but in practice - contamination risks can drop significantly.

Generic drugs saved the U.S. healthcare system over $300 billion in the last decade. They’re essential. But they shouldn’t come with hidden dangers. The next time you pick up a prescription, remember: safety isn’t automatic. It’s something we all have to fight for - together.

How can I tell if my generic drug is contaminated?

You can’t always tell by looking. But if your pill looks different - new color, unusual spots, odd smell, or texture - ask your pharmacist. If you experience new or worsening side effects after switching to a generic, report it to MedWatch. Contamination often shows up as unexpected reactions, like rashes, nausea, or fatigue that didn’t happen before.

Are all generic drugs unsafe?

No. Most generic drugs are safe and effective. The FDA requires them to meet the same standards as brand-name drugs. But contamination risks are higher because many manufacturers operate on thin margins and rely on overseas production with less oversight. The problem isn’t generics themselves - it’s inconsistent quality control.

Why are generic drugs more likely to be contaminated than brand-name ones?

Brand-name companies often have more money to invest in modern facilities, better cleaning systems, and rigorous testing. Generics are sold at lower prices, so manufacturers cut corners to stay profitable. Older factories, less training, and fewer inspections increase the risk. FDA data shows generic facilities have nearly 60% more contamination-related violations than brand-name ones.

What should I do if I think my medication is contaminated?

Stop taking it immediately. Contact your doctor or pharmacist. Report the issue to the FDA’s MedWatch program at fda.gov/medwatch. Keep the pill bottle and packaging - they help investigators trace the source. Don’t return it to the pharmacy without reporting it first.

Can pharmacies test drugs for contamination?

Most community pharmacies can’t do lab tests. But they can spot obvious signs - discoloration, strange odors, crumbling pills. Hospital pharmacies sometimes have access to basic testing. If you’re concerned, ask your pharmacist if they know the manufacturer and whether they’ve seen issues with that batch. You can also check the FDA’s drug recall database online.

Joseph Snow

January 4, 2026 AT 12:17The FDA is a joke. They inspect 1% of shipments? That’s not oversight-that’s negligence dressed up as bureaucracy. I’ve seen pills with visible mold in my generic blood pressure med. They told me it was ‘just dust.’ Dust doesn’t grow. And yet, no recall. No apology. Just another ‘patient report under review.’ This isn’t healthcare. It’s Russian roulette with a prescription pad.

Akshaya Gandra _ Student - EastCaryMS

January 5, 2026 AT 17:20hi! i’m from india and work in a pharma lab. yes, we are under pressure. yes, cleaning is expensive. but not all factories are bad. my plant uses closed systems and real-time sensors. we lost 2 clients last year for not cutting corners. i know it sounds weird, but we care. maybe the system is broken, but people like me are trying. dont blame all of us.

Enrique González

January 7, 2026 AT 07:49My mom’s on generic metformin. She started getting dizzy last month. I checked the bottle-different logo, darker pill. I called the pharmacy. They said ‘it’s the same drug.’ But it wasn’t. I filed a MedWatch report. Two weeks later, the batch got pulled. Don’t wait to get sick. Check your pills. Ask questions. Your life isn’t a cost-cutting experiment.

saurabh singh

January 8, 2026 AT 03:26Hey man, I get the fear. But let’s not paint all Indian factories with the same brush. I’ve seen plants in Hyderabad that look like NASA labs-clean rooms, AI monitoring, even drone inspections. The problem isn’t the country-it’s the middlemen. The middlemen who buy cheap and sell fast. If you want safer generics, support the brands that invest. Not the ones who bid lowest and vanish after the contract.

John Wilmerding

January 9, 2026 AT 05:06From a clinical pharmacist with 18 years in community pharmacy: The most underutilized tool in contamination prevention is patient reporting. Over 80% of contamination incidents are first detected by patients or pharmacists-not regulators. Document everything: pill appearance, lot number, symptoms. Submit to MedWatch. Then follow up. The system only works when people hold it accountable. Don’t assume someone else will do it. Your report could prevent a death.

Peyton Feuer

January 10, 2026 AT 14:47My grandma switched to a new generic and got a rash. We didn’t make a big deal-until she started coughing up blood. Turned out the batch had silica particles. We reported it. Got zero response. Now I just buy name-brand, even if it costs 3x. I’d rather pay more than bury someone because we were too tired to fight. It’s not fair. But it’s real.

Cassie Tynan

January 12, 2026 AT 13:02So we’re supposed to trust a system where the people who make the drugs also write the rules, and the people who enforce them are underfunded, overworked, and legally barred from inspecting more than 1% of shipments… and yet, we’re supposed to be grateful they’re ‘cheaper’? I’m starting to think the real contamination is in our collective willingness to accept this as normal.