Low Density Material Selector

Select a material to view its properties.

Select a material to view design considerations.

Decision Matrix Summary

Compare materials using the table below to understand trade-offs in density, strength, thermal performance, and cost.

| Material | Density (kg/m³) | Compressive Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use | Relative Cost |

|---|---|---|---|---|---|

| Expanded Polystyrene (EPS) | 15-30 | 0.3-0.7 | 0.030 | Insulated concrete forms, wall sheathing | Low |

| Aerogel | 130-150 | 0.5-1.0 | 0.013 | High-R façade panels, retro-fit blankets | High |

| Cellular Concrete | 1,200-1,600 | 5-20 | 0.090 | Non-structural walls, precast units | Medium |

| Structural Insulated Panels (SIPs) | 200-350 | 10-30 | 0.020-0.040 | Walls & roofs, fast-track builds | Medium-High |

| Bamboo Laminated Panels | 300-600 | 30-70 | 0.060 | Structural beams, interior cladding | Low-Medium |

| Recycled Plastic Lumber | 550-750 | 15-25 | 0.045 | Decking, exterior cladding | Medium |

When architects and builders talk about "lightweight" today, they’re not just dreaming of easier lifts on the site. They’re leveraging a family of low density materials that cut weight, boost energy efficiency, and shrink a building’s carbon footprint-all without sacrificing strength.

Quick takeaways

- Low density materials lower structural loads, allowing slimmer beams and smaller foundations.

- Many offer superior thermal insulation, which reduces heating and cooling bills.

- Recycled or bio‑based options (like bamboo) boost sustainability credentials.

- Designing with these materials requires attention to fire rating, moisture resistance, and connection details.

- A side‑by‑side comparison helps pick the right product for each project.

What qualifies as a low density material?

Low density materials are construction products whose mass per unit volume (density) is significantly lower than traditional options like concrete or steel, typically under 800kg/m³. Their lightness comes from trapped air, porous structures, or the use of lightweight natural fibers. Because they carry fewer dead loads, engineers can design slimmer structural members, reduce foundation size, and even extend spans that would be impractical with heavier stuff.

Key benefits for modern building projects

- Weight reduction: Lighter walls mean smaller footings and less seismic demand.

- Thermal performance: Many low density products double as insulation, cutting energy use.

- Speed of construction: Prefabricated panels can be lifted and installed quickly.

- Sustainability: Recycled or renewable sources lower embodied carbon.

- Design flexibility: Thin, high‑R panels enable creative façade treatments.

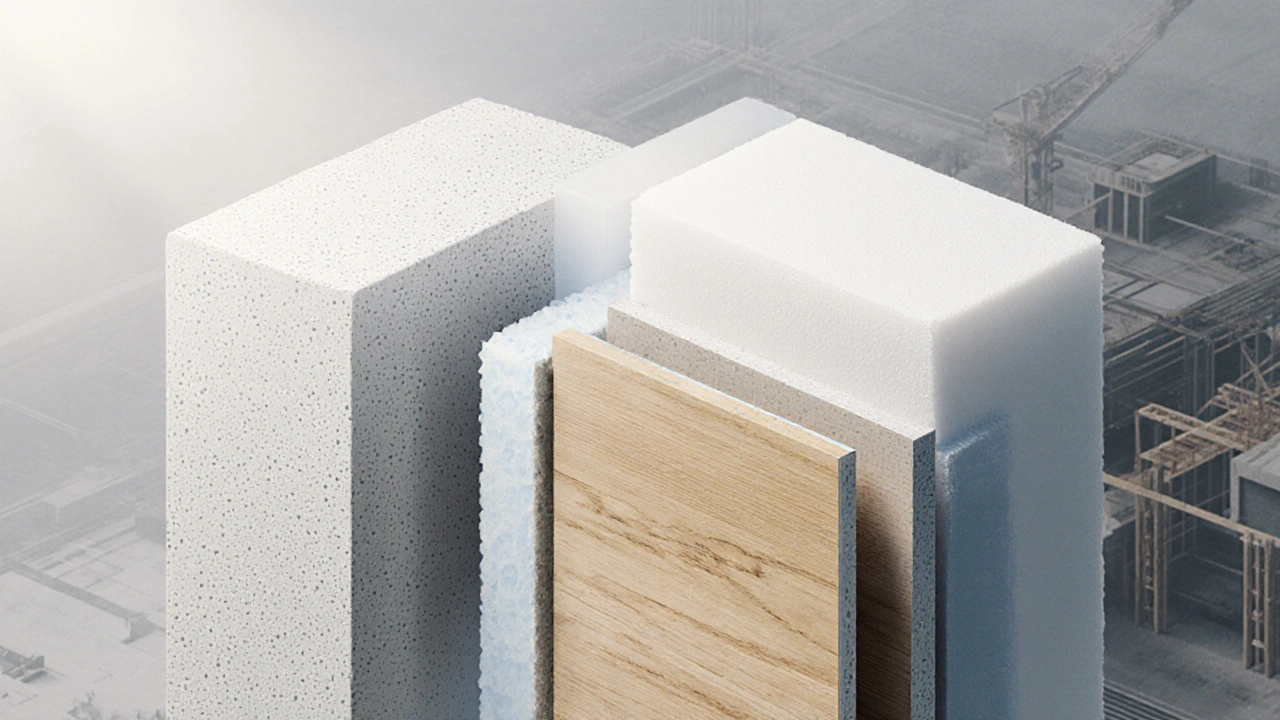

Popular low density materials on the market

Below are the most widely used options, each with its own strength‑to‑weight profile.

Expanded polystyrene (EPS) a rigid foam made from tiny polymer beads, commonly used for wall insulation and as a lightweight fill boasts densities as low as 15kg/m³ and a thermal conductivity around 0.030W/m·K. Its closed‑cell structure resists moisture absorption, making it a favorite for insulated concrete forms (ICFs).

Aerogel often called "frozen smoke," this silica‑based material features a porous network that traps up to 99.8% air delivers the lowest thermal conductivity of any solid (≈0.013W/m·K) while staying lightweight (≈150kg/m³). It’s ideal for high‑performance façades and retrofits where space is at a premium.

Cellular concrete also known as lightweight concrete, contains air bubbles introduced via a foaming agent during mixing typically weighs 1,200-1,600kg/m³-still lighter than normal concrete (≈2,400kg/m³). Its compressive strength ranges from 5 to 20MPa, making it suitable for non‑structural walls and precast panels.

Structural insulated panels (SIPs) are sandwich assemblies that combine two facing boards with a core of foam or aerogel. The panel’s overall density usually falls between 200 and 350kg/m³, and the integrated insulation can achieve R‑values of 30+ per foot of thickness.

Bamboo a fast‑growing grass that can be processed into laminated panels, beams, and flooring has a density of 300-600kg/m³ and a tensile strength rivaling some steel grades. Its renewability and low embodied energy make it a hot choice for eco‑friendly design.

Recycled plastic lumber is made from post‑consumer PET or HDPE waste, extruded into rigid boards typically weighs 550-750kg/m³ and resists rot, insects, and moisture, perfect for decking, railing, and exterior cladding.

Lightweight steel framing uses thin‑walled C‑ or Z‑sections that offer high strength at reduced weight compared to traditional hot‑rolled sections can lower member weight by 30-40% while maintaining load‑bearing capacity, especially when paired with insulated panels.

Design considerations and best‑practice tips

- Fire rating: Materials like EPS need protective sheathing or intumescent coatings to meet fire codes. Aerogel is non‑combustible, while bamboo requires treatment.

- Moisture management: Even low‑density foams can absorb water if damaged. Use vapor barriers and seal joints carefully.

- Connection detailing: Because the substrate is lighter, fasteners must be sized for the material’s shear and pull‑out capacity. Designers often embed steel plates or use specialty anchors.

- Acoustic performance: Lightweight panels can transmit sound more readily. Adding resilient channels or mass‑loaded vinyl helps meet sound‑rating requirements.

- Cost vs. performance: Aerogel offers unmatched R‑value but commands a premium price. EPS and cellular concrete deliver good performance at a fraction of the cost.

Real‑world examples

Case1 - High‑rise office tower (Seattle, 2023): The project used SIPs with an aerogel core for the façade, slashing wall thickness by 40% while achieving an overall U‑value of 0.12W/m²·K. The lighter envelope allowed a 15% reduction in steel framing weight.

Case2 - Affordable housing (Austin, 2024): Expanded polystyrene ICF walls sped up the build schedule by 25% and delivered a 30% energy‑use reduction compared to conventional masonry.

Case3 - Eco‑resort (Costa Rica, 2025): Bamboo laminated panels formed the primary structure, giving the resort a carbon‑negative rating thanks to the material’s rapid regrowth and low transport emissions.

Choosing the right low density material - a quick decision matrix

| Material | Density (kg/m³) | Compressive Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use | Relative Cost |

|---|---|---|---|---|---|

| Expanded Polystyrene (EPS) | 15-30 | 0.3-0.7 | 0.030 | Insulated concrete forms, wall sheathing | Low |

| Aerogel | 130-150 | 0.5-1.0 | 0.013 | High‑R façade panels, retro‑fit blankets | High |

| Cellular Concrete | 1,200-1,600 | 5-20 | 0.090 | Non‑structural walls, precast units | Medium |

| Structural Insulated Panels (SIPs) | 200-350 | 10-30 | 0.020-0.040 | Walls & roofs, fast‑track builds | Medium‑High |

| Bamboo Laminated Panels | 300-600 | 30-70 | 0.060 | Structural beams, interior cladding | Low‑Medium |

| Recycled Plastic Lumber | 550-750 | 15-25 | 0.045 | Decking, exterior cladding | Medium |

Checklist for integrating low density materials

- Confirm fire‑rating compliance for the selected material.

- Design connections based on manufacturer‑provided pull‑out and shear values.

- Plan for moisture barriers where foam products meet water‑prone zones.

- Validate structural analysis with reduced dead‑load inputs.

- Factor in transportation weight savings for logistics planning.

- Check local building codes for permissible use of renewable composites.

Frequently Asked Questions

Are low density materials safe for high‑rise construction?

Yes, when engineered correctly. Materials like SIPs and lightweight steel framing meet or exceed the same code‑required strength and fire performance as traditional systems, provided that connections and protective layers are specified according to the manufacturer’s data.

How do low density panels affect energy consumption?

Because many of these products double as insulation, they lower the building envelope’s U‑value dramatically. In a typical office retrofit, using aerogel‑core panels can cut heating and cooling loads by 30‑40% compared to standard brick walls.

What is the environmental impact of using EPS?

EPS itself is petroleum‑based, but its lightweight nature reduces transport emissions. Moreover, many manufacturers now incorporate recycled polystyrene into the mix, improving the material’s overall embodied carbon profile.

Can I combine bamboo with other low density products?

Absolutely. Bamboo beams are often used alongside SIP wall panels to create a hybrid system that leverages bamboo’s high tensile strength with the panel’s insulation value, delivering a truly green building envelope.

Is there a risk of moisture damage with cellular concrete?

Cellular concrete is more porous than dense concrete, so designers place vapor‑permeable membranes and ensure proper drainage to avoid long‑term moisture retention.

How do I price a project that uses low density materials?

Start with material cost per square foot, then add savings from reduced labor, smaller foundations, and lower transportation weight. A quick rule of thumb: subtract 5-10% from the total budget for every 100kg/m³ reduction in structural dead load.

Scott Richardson

October 1, 2025 AT 14:04Our builders know better than any foreign wannabe. We have the best tech and the strongest code.

Laurie Princiotto

October 3, 2025 AT 16:00Wow, like that’s really something :), but I guess the article could have mentioned the downsides too.

Justin Atkins

October 5, 2025 AT 23:33From a structural engineering perspective, the reduction in dead load afforded by low‑density composites directly influences the sizing of primary load‑bearing members, thereby allowing for slimmer sections without compromising safety. Moreover, the thermal mass reduction synergizes with integrated envelope insulation to produce a net decrease in HVAC demand. The annexed material matrices demonstrate a clear trade‑off curve between compressive strength and thermal conductivity, which must be evaluated in the context of life‑cycle cost analysis.

June Wx

October 8, 2025 AT 07:06Honestly, the article missed the emotional side of living in a lighter building. It feels like the whole place breathes easier, and that’s priceless.

kristina b

October 10, 2025 AT 14:40When one contemplates the profound ramifications of integrating low‑density materials into the very fabric of our built environment, one must first acknowledge the historic weight of tradition that has long shackled architectural ambition. The very notion of a structure that seemingly defies gravity invites a philosophical discourse on the relationship between mass, meaning, and modernity. Each kilogram saved is not merely a numerical datum; it represents an opportunity to reimagine spatial dynamics, to allocate floor area where none once existed. Consider, for instance, the liberation of foundation design, wherein the diminished dead load permits a reduction in concrete volume, thereby curtailing embodied carbon. This cascade of benefits extends to transportation logistics, as lighter shipments alleviate fuel consumption and emissions. Moreover, the thermal virtue of many of these materials, such as aerogel’s unparalleled R‑value, translates directly into operational energy savings, granting occupants a more comfortable, sustainable habitat. The aesthetic possibilities are equally compelling: the translucency of aerogel panels enables daring façades that play with light in ways previously reserved for art installations. Yet, with such promise comes responsibility; fire safety, moisture management, and acoustic performance must be judiciously addressed lest we sacrifice safety for novelty. This balance between innovation and regulation underscores the necessity of rigorous testing and code development. In the grand tapestry of architectural evolution, low‑density materials constitute a vibrant new thread, weaving together efficiency, beauty, and ecological stewardship. As we stand at this crossroads, let us embrace the challenge, celebrate the potential, and forge a future where our structures are as light in impact as they are in mass.

Ida Sakina

October 12, 2025 AT 22:13One must recognize that the moral imperative to reduce embodied carbon demands the adoption of such material technologies. The ethical dimension cannot be ignored.

Amreesh Tyagi

October 15, 2025 AT 05:46But i think the article forgets that low density sometimes means low durability and that can be a problem

Brianna Valido

October 17, 2025 AT 13:20Super excited about the possibilities! 🌟 Light buildings mean faster builds and happier owners! 😄

Caitlin Downing

October 19, 2025 AT 20:53i think the post is great but it could use a bit more detail on acoustic properties. also the table could be more clear.

Robert Jaskowiak

October 22, 2025 AT 04:26Sure, because everyone’s first concern is whether the foam will squeak when you walk on it. 😂

Julia Gonchar

October 24, 2025 AT 12:00Just to add, the compressive strength of cellular concrete, while lower than traditional concrete, still meets most non‑structural load requirements and offers excellent fire resistance.

Vic Harry

October 26, 2025 AT 18:33America leads.

Suman Wagle

October 29, 2025 AT 02:06Ah, the noble quest for ever‑lighter walls-how delightfully ironic that we must still anchor them to the same stubborn foundations of the past.

Neil Sheppeck

October 31, 2025 AT 09:40Let’s keep the conversation inclusive: whether you pick bamboo or aerogel, the key is sharing knowledge and supporting each other’s projects.